Victron’s DVCC Function Explained

One of the most important and unique advantages of using Victron Energy equipment is the ability to utilize its native DVCC function. DVCC is simple, powerful, and at first glance, confusing. In this article, we’ll discuss what it is and how it works to coordinate systems-level control over multiple charging sources to safely manage a battery bank.

Firstly, DVCC stands for Distributed Voltage and Current Control

- Distributed - A network of components

- Voltage & Current - The battery parameters we want to regulate

- Control - How parameters are managed

When activated, DVCC allows individual components—whether produced by Victron Energy or a line of products supported and integrated by Victron—to work together using the same information to charge and discharge the batteries.

When activated, DVCC allows individual components—whether produced by Victron Energy or a line of products supported and integrated by Victron—to work together using the same information to charge and discharge the batteries.

The Challenge

Traditionally, in a distributed power system with multiple charging components (like multiple solar charge controllers, a charge controller and an inverter, or an inverter and a wind turbine), you would need to set the charging parameters for each component. In some instances, you can synchronize them, such as pairing two Midnite solar charge controllers to function as one.

The challenge is that the inverter is often not synchronized with the rest of the system. When the generator starts, the inverter begins charging the batteries, which increases their voltage. This causes the solar charge controller to shut off, incorrectly assuming the batteries are fully charged. A classic example of this from our past is in combined wind and solar systems, where charging occurs exclusively through either wind or solar, but not both simultaneously.

So what can we do in this situation? How do we get all the chargers to work together? Victron's solution to this is thoughtful, complete, and, depending on your battery of choice, it’s automatic.

How DVCC works

DVCC is a program that lives inside of a GX device, like the Cerbo or Ekrano. In a Victron power system, a GX device serves as a gateway, connecting the Victron inverter/charger with other devices, such as a solar charge controller or a communicating lithium battery.

With a communicating battery bank, DVCC responds to the batteries to adjust the following parameters:

- Limit Charge Current. This means that you can limit the charge current globally to the batteries. If you had 200 Amps of potential charge but your battery cable or batteries were only good for 100 Amps, you can address that right here. Additionally, as your batteries near their full point, or when they are dealing with balancing themselves internally, they can adjust the maximum charge current downwards as needed (this is only possible in a communicating system).

- Limit Charge Voltage. If your batteries are not Pylontechs, then you can put in a number that will ensure your batteries will never be charged greater than this amount.

- Maximum Discharge Current. This is monitored with communicating batteries, and the inverter regulates the maximum discharge current. It is not an option for non-communicating batteries.

- Shared Voltage Sense. This will let you pick from the various devices and select the one you want to use as a voltage source for DVCC.

- Shared Temperature Sense. Similarly, it will populate the temperature sensor options, allowing you to pick the one you want to use.

- Shared Current Sense. If you did not have communicating batteries, this would be your shunt. If you have Pylontech batteries, all of this is done for you via the “forced on” feature they enjoy with Victron.

What does DVCC do with this information? It shares it with every other enabled device in the system so that they are all operating off of the same information at the same time.

The Control aspect of DVCC is worth understanding. Where do we get our input for decision-making? It's important that all the devices are using the same voltage and temperature, for example. If you have a Victron SmartShunt, you may want that to be your voltage source. If your inverter has a temperature probe, use that for battery temperature, not the solar charger's internal ambient temperature.

It's very common to see a 10th-of-a-volt difference from the battery all the way up through the fusing to the solar charge controller. This voltage drop will tell the solar controller there is a reduced battery voltage, and therefore, it will charge at a higher voltage. When the other devices see that higher voltage, they will kick off prematurely. By having a global accurate battery voltage value, all the devices can work together.

Because we have confidence in knowing where the control inputs are coming from, we can set global maximum voltages and maximum (combined) currents for the batteries.

Does battery choice matter?

The inverter’s main job is to pull power out of the batteries, so it’s very important to know what your max discharge current is and what your state of charge is for the discharge cycle. That information must be provided by the batteries themselves to ensure accuracy without constant recalibration.

In previous articles, we unpacked commonly used terms around battery-inverter communication and described why closed-loop communication is necessary for the management of modern lithium battery banks. In a closed-loop system, the battery reports a constant stream of real-time state of charge, voltage, and temperature data with the inverter via a coms cable. There’s no guess work; there’s no middle-man in the form of a battery shunt. Accurate data is being shared from the source (the battery’s BMS), and the rest of the system can respond appropriately by backing off or increasing the charge current.

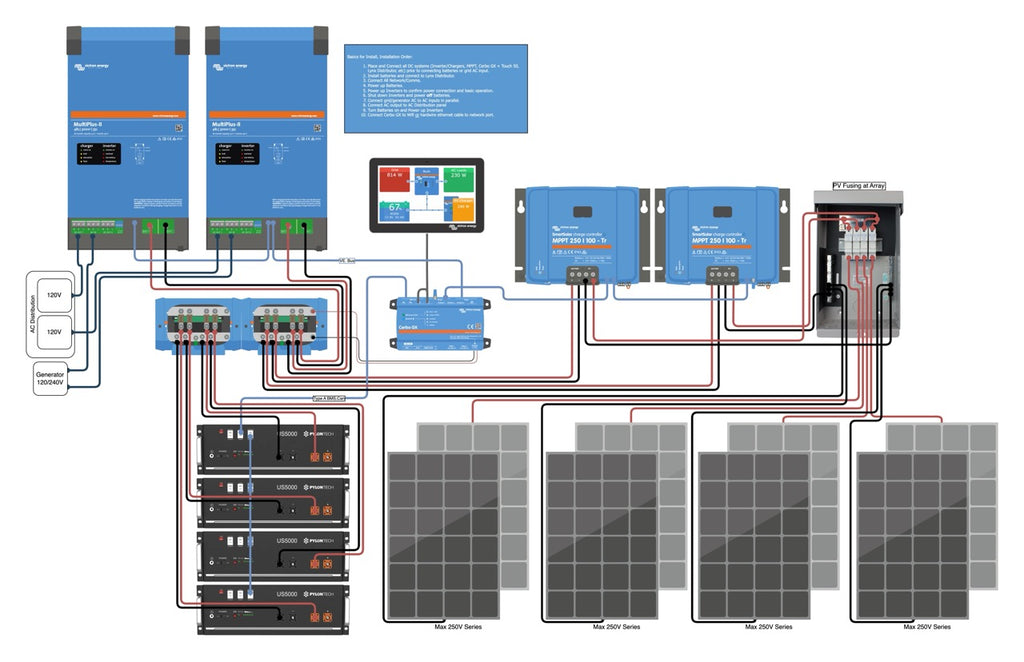

48V 5000 Volt Amp Split Phase Victron Power System with two 250/100 SmartSolar MPPT solar charge controllers and 4 Pylontech Pylontech US5000 LiFePO4 batteries and 4000-5000W of PV.

DVCC is part of the reason why Pylontech batteries are so effective when paired with Victron systems. When the comms cable is plugged in, Victron inverters/chargers immediately identify Pylontech as the connected battery, force DVCC on, and make all the adjustments to maximum current and charge voltage limits for all the devices through this system. Of course, the adjustments are dynamic and allow for perfect charging every time.

Of course, this dreamy, hands-free battery-inverter communication isn’t a fluke, and it isn’t found with budget-brand lithiums. It’s the result of many years of intensive collaboration on the part of both companies to develop an integration between their products. As such, few battery manufacturers have achieved this level of integration with Victron Energy - it takes a long time, it’s expensive, and you need an intelligent BMS that can handle it. (For more on this, read Bad, Better, Best: Battery-Inverter Communications & Compatibility).

If your batteries are not fully communicating, the various charging parameters of the connected devices are not taken over, so you will need to set those parameters manually based on the battery manufacturer's specifications. Always look for ‘Suggested’ rather than 'Maximum' values here, as many company’s marketing teams write the spec sheet. We always advise that you set up each component as if it were operating independently and then bring them into the network. That way, if you lose that network because a mouse took a bite out of a network cable or a houseguest unplugged your Cerbo, the system can still operate without the risk of charging your batteries incorrectly.

Advantages of utilizing DVCC

1. Greater system reliability and long-term performance

The primary advantage offered by Victron’s DVCC function is that all the devices in a system can work together. If, say, the sun is out and your generator starts, there could be a potential to over-current your battery bank. We are never overworking our battery bank (letting it discharge too far down or overcharging it), which relates directly to battery health and expected life span. If you already have a Victron system or are designing systems around Victron equipment, we highly recommend using a battery that can take full advantage of this DVCC function. In our world, a common question is, “Does it work with DVCC?” because it's the cornerstone of a lot of the advanced battery functionality we have grown to expect.

2. Incredible flexibility in system design

To overcome the challenge of managing multiple charging sources described earlier, some manufacturers now include other system components, such as solar charge controllers, in the inverter package in order to provide an ‘all-in-one’ solution. Why do they do this? In some cases, it can be a way to manage the system automatically. By including the solar charge controller in the inverter package, the solar charge controller can operate off of the information the inverter receives through closed-loop communication. However, not all “all-in-one” type solutions will offer this same level of functionality. Be sure to check any option you’re looking at closely to make sure that your solar won’t be shut off every time you run your generator, as does happen in many systems with communications that can’t match the sophistication that Victron offers.

All-in-one systems work great as long as they perfectly match the needs your application. As soon as you need to step “outside of the box” (literally outside of the all-in-one box), you now have the problem of figuring out how to include a new charge source (or even a new load) with your existing system.

This is where Victron’s DVCC function - and modular product design - really shines. If you have a Victron system, you can add components and synchronize them with DVCC. If your loads are too big for a 10K inverter/charger, you can use two 8Ks. If you need more power than a large charge controller can provide, you can use two medium MPPT charge controllers. If you’ve ever felt slightly overwhelmed looking through Victron’s extensive product line (60+ different sizes of SmartSolar MPPTs), it’s because Victron has intentionally designed products that are the perfect fit for a wide variety of use cases - and yet have tremendous flexibility built-in, thanks to DVCC. This is what allows those working with Victron gear to join different products together in a nearly endless number of combinations to create a system with the exact performance specifications we want.

3. Product integrations that add value without adding complexity

What excites us most here at Intelligent Controls are devices that work inside this DVCC functionality to unlock even more reliability, efficiency, or added controls within a Victron power system. This includes the Hatz fiPMG generator, the Zeus high-energy external alternator regulator, Pylontech batteries, the new Orion DC to DC chargers, and more products to come.

In a trailer-mounted power system utilizing a Hatz CAN-bus controlled generator, we can take advantage of Victron’s DVCC function to turn the generator ON or OFF based on a lithium battery bank’s state of charge.

In a grid-connected hybrid generator system, we can still utilize dirty or inconsistent grid power to charge a Pylontech battery bank when it’s available while still accepting solar input from a solar array without any risk of overcharging our battery bank.

We can grab the DVCC control data in Node-RED and use it to modulate grid tie inverters, which gives us fantastic command and control for AC-coupled systems.

In an RV with an external alternator, we can leverage a Zeus external alternator regulator to safely charge a lithium battery bank while driving, minimizing the use of an onboard generator.

DVCC makes these complex coordination efforts possible by allowing core components—produced by Victron or products supported and integrated by Victron—to work together using the same information to charge and discharge the batteries.

How can Victron’s DVCC function be put to work in your power system design? Send us a message here to start a conversion with our team. We’re happy to share what we know.

Related Articles:

Bad, Better, Best: Battery-Inverter Communications & Compatibility

Active Management: Expect More From Your BMS

Shop LiFePO4 batteries

Pylontech 12V LiFePO4 Battery

PylontechBring your mobile application into the 21st century and throw away your shunt with a modern, drop-in battery. Pylontech’s RT12100G31 has it all: It...

View full detailsPylontech Pelio 48V LiFePO4 Battery

PylontechOverview Did you Know? Pylontech's Pelio-L-5.12 is a modular 5.12KWh, 100Ah lithium battery suitable for a wide range of home standby and off-g...

View full detailsLithium Battery 12.8V & 25.6V Smart

Victron EnergyAvailable in 12.8 and 25.6V models, Victron Energy's Smart Lithium is a robust, heavy-duty LiFePO4 battery with a high charge and discharge capacit...

View full detailsPylontech US5000 48 Volt LiFePO4 Battery

PylontechThe Pylontech US5000 offers unparalleled reliability and power delivery. This 48V rack-mount sets a standard that other form-factor lithium batteri...

View full detailsPylontech UP2500 24V Lithium Battery

PylontechMany modern mobile power systems can benefit from the higher power delivery of 24V. Pylontech's 24V UP2500 delivers 2.84kWh of power and offers al...

View full details